Printing

Print is a big deal. Whether offset, toner, or inkjet the magic of the printed sheet is something that will never go away. We’ve watched this industry go through all kinds of changes yet it has always come out larger and better than ever.

Today commercial printing is done mostly across 3 major processes.

- Offset Printing: Printing presses use wet offset ink to make lithographic copies of a printing plate.

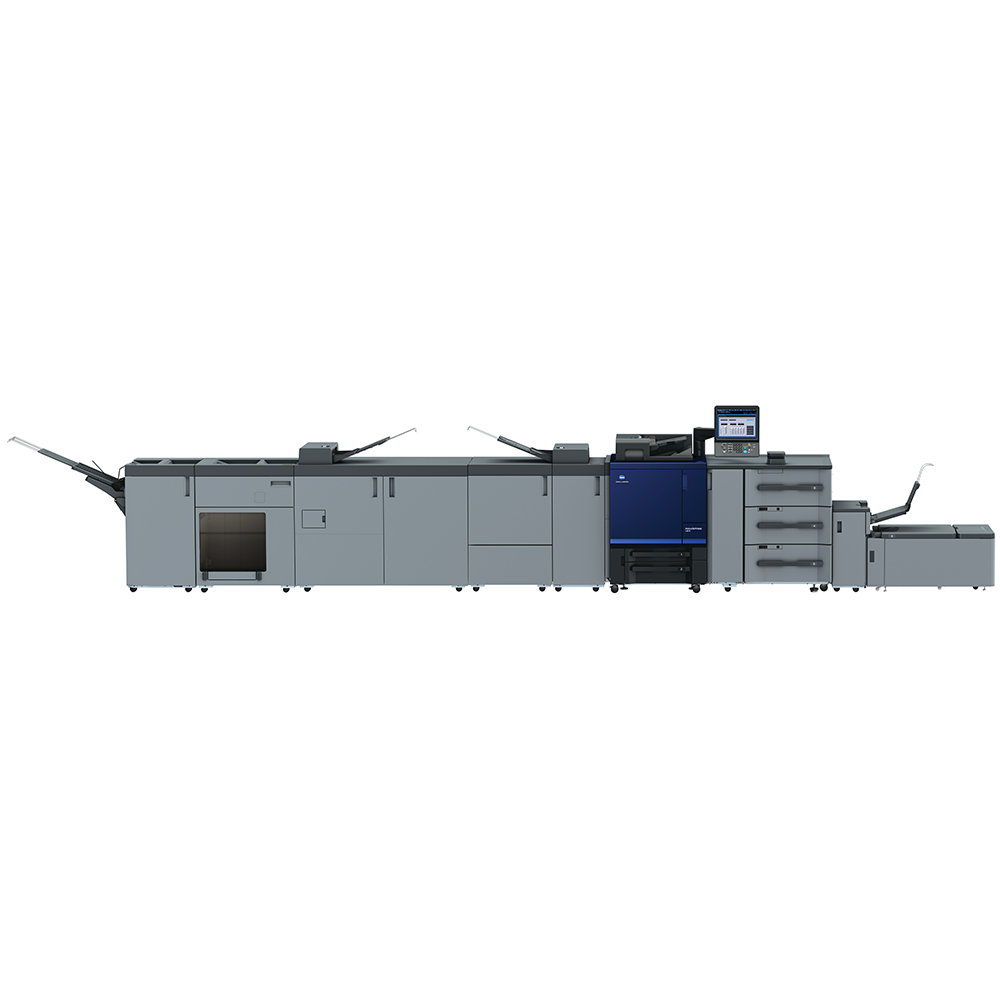

- Digital Printing: This term generally refers to toner-based digital presses. They are commonly also called copiers although they have outgrown that nickname.

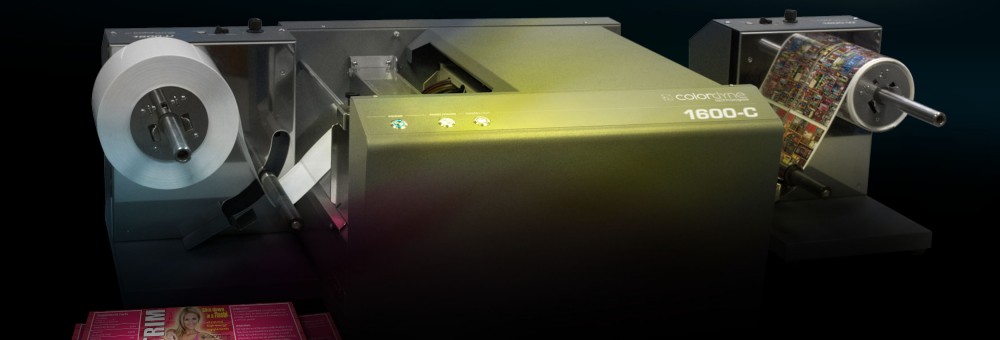

- Inkjet Printing: Inkjet has been around for a long time. A new generational change is coming with waterfall style inkjet heads that print at very high quality for extremely low cost.